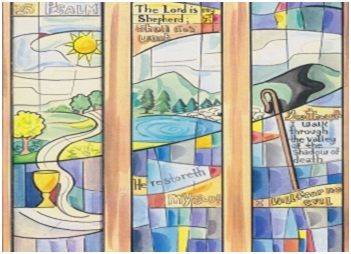

The methods of the stained glass craft have changed very little since the Middle Ages. The handcrafted stained glass a window involves many stages and is a lengthy process. A stained glass window is made of pieces of glass assembled together with lead often traditional stained glass windows are painted. The art of stained glass is unique because of the relationship between the glass and light. Light is needed for the stained glass to come alive and be vibrant.

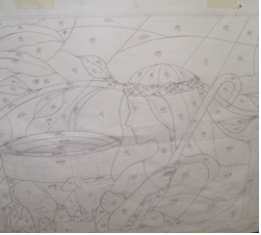

The sketch is the first of the many stages of a stained glass window. This represents the preliminary step in the creation of a stained glass window and becomes the master plan of the project. Any changes can be made at this time. Once the sketch is agreed upon and approved, the project begins.

DESIGN

The design is a full size drawing of the final design that then becomes the work drawing for the fabrication of the window. The design is squared-up for the exterior size and drawn by hand in the studio with precise scaled measurements according to the sketch.

GLASS SELECTION AND COLORATION

The color selection is an essential element for a successful stained glass window, it is important to select just the right glass, color and texture. A color scheme is selected from color palets that contain many shades of glass from the studio. Pieces of glass are held up to daylight to see the effect of the colors together and seek interesting textures or variations within a sheet of glass. Since the color selection is an extremely important part of the project, a great deal of time and consideration are spent on this phase of the project. Every piece of glass in the inventory has a separate identification number. The design will be used to indicate the assignment of the glass numbers.

PATTERNING

When the design has been completed and glass selections have been made, the next step is the Patterning. The white paper design is placed over thick brown pattern paper with a layer of carbon paper between the cartoon and the pattern paper. The design is re-drawn with a red pen down the exact center of each lead line, so as to transfer the cut-lines onto the thick pattern paper. The tracing of the lead lines of the design delineates each individual pattern piece.

These thick paper patterns are then cut with special three-bladed pattern shears that simultaneously cut out a very narrow strip of paper. This narrow strip of paper corresponds to the width of the lead came core, thus eliminating the paper equal to the heart of the lead came that goes between the glass. Once the paper patterns are cut, they are sorted according to glass color number and are ready to be used to cut the glass.

GLASS CUTTING

Cutting the glass from the pattern pieces is the next step in the stained glass process. The appropriate thick paper pattern is placed on desired color of glass. Each piece of glass is hand cut to the shape of the pattern using a steel or carbide wheel glass cutter specifically designed to cut stained glass. The cut pieces of glass are placed onto the design that has been secured on the workbench that becomes the work drawing ready for the glazing process.

GLAZING

After the glass has been cut and sometimes painted, it will be placed back on the cartoon work drawing that has been nailed down on the workbench; the glass is now ready to be assembled into the lead came.

After the lead has been cut and glass is in place, flux is applied to each of the many lead joints then soldered together with a soldering iron. Both sides of the window must be soldered then the flux must be cleaned off the window. The function of the lead came is to give the stained glass integrity and structure, as well creating an artistic design within the window.

INSTALLATION

The final process is the stained glass installation. Often the window has a piece of window glass or Tempered glass on the outside. The new window will usually be installed from the inside and placed against the existing clear glass using various methods of securing the window in place. It is not necessary to make these into commercially insulated units.